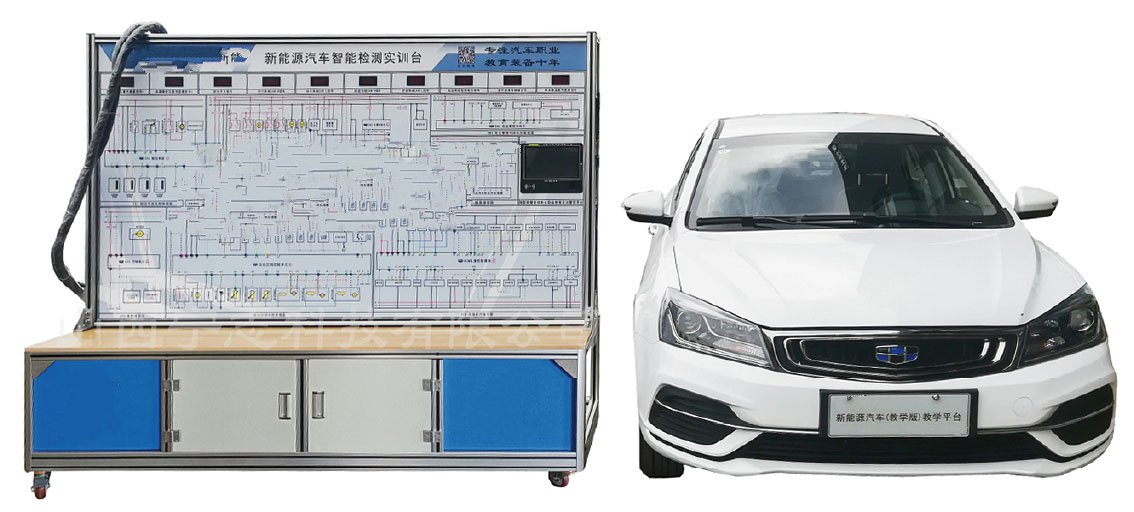

Products

New Energy Vehicles-Complete Vehicle Teaching Platform

Product model: NZX-01

Main parameters:

Vehicle type: pure electric passenger car

Working temperature: -20℃~50℃

Test platform weight: 70kg

Detection platform size: 2000*800*1800mm

Performance characteristics:

1. The vehicle teaching platform is made of pure electric vehicles, including pure electric vehicles for teaching and external detection teaching platforms;

2. On the basis of maintaining the technical status and function display of the original vehicle, the motor controller, on-board charger, high-voltage distribution box, DC/DC converter, drive motor, vehicle VCU, power battery pack, air conditioning system, steering system, shift lever, ABS control unit and other systems of the pure electric vehicle are connected to the teaching detection platform through a lossless external connection;

3. The teaching detection platform is equipped with circuit diagrams of each system, working status display devices, signal detection terminals, and IoT intelligent information vocational education training management platform. It is connected to the vehicle systems through adapter boxes and special wiring harnesses, and can perform fault settings and data collection of various systems of the vehicle, which is convenient for students to carry out line maintenance, fault diagnosis, vehicle training and other practical training contents;

4. Pure electric vehicle and external detection teaching platform wiring harness It is very convenient to connect and disconnect. After connecting to the detection system, you can conduct system detection and diagnosis and other practical training. After disconnecting the detection teaching platform, the electric car can drive normally;

5. The teaching detection platform needs to lead out the terminals of each system to be detected. The detection terminals are selected from high-temperature, high-voltage and corrosion-resistant safety terminals. There is no need to plug and unplug the original car connector. On the teaching detection platform, you can use a multimeter and an oscilloscope to detect the resistance, voltage, frequency, waveform, etc. of each system;

6. The teaching detection platform frame is made of high-grade aluminum alloy profiles. The frame is equipped with an operating platform for placing tools, materials and other items. The operating platform is equipped with a material placement cabinet under the operating platform, which is convenient for placing materials and other items, and convenient for teaching;

7. The base of the teaching detection platform is equipped with a self-locking caster device, which is convenient for moving at any time;

8. The teaching detection platform is equipped with a power emergency stop switch, which is convenient for cutting off the main power supply and safety protection in an emergency;

9. Equipped with equipment training instructions, the contents of the manual include daily maintenance, maintenance information, fault settings of the equipment Data, operating specifications, operating procedures, operating precautions, etc.;

10. The equipment is equipped with a training QR code. Teachers and students can use the vocational education teaching information mobile platform (APP) to scan the QR code to watch the teaching video of this stand, including: equipment usage specifications, operating precautions, equipment maintenance methods, etc.;

11. Training projects:

1. Data analysis, fault diagnosis and troubleshooting of the motor control (PEU) system; 2. Data analysis, fault diagnosis and troubleshooting of the charging (OBC) system; 3. Data analysis, fault diagnosis and troubleshooting of the battery management (BMS) system; 4. Data analysis, fault diagnosis and troubleshooting of the vehicle control (VCU) system; 5. Data analysis, fault diagnosis and troubleshooting of the air conditioning system; 6. Data analysis, fault diagnosis and troubleshooting of the DC/DC converter; 7. Data analysis, fault diagnosis and troubleshooting of the power drive motor system; 8. Data analysis, fault diagnosis and troubleshooting of the steering system; 9. Routine maintenance and operation training of the vehicle system; 10. Brake fluid 11. Operation training of brake pad replacement; 12. Operation training of refrigerant leak detection, pressure, vacuuming and refrigerant filling in air conditioning system; 13. Operation training of power battery pack disassembly and assembly; 14. Operation training of vehicle four-wheel alignment; 15. Cognition of high-voltage electronic control assembly structure; 16. Training of the structure and working principle of motor controller module; 17. Training of the structure and working principle of DC-DC converter module; 18. Operation training of vehicle AC slow charging; 19. Operation training of vehicle DC fast charging; 20. Cognition of the structure and working principle of accelerator pedal; 21. Signal detection training of accelerator pedal; 22. Cognition of the structure and working principle of shift mechanism; 23. Signal detection training of shift mechanism; 24. Circuit testing training of power battery pack; 25. Training of plugging and unplugging method of high-voltage connector of whole vehicle; 26. Measurement training of relay and fuse box; 27. Disassembly and assembly training of electronic handbrake motor;

12. Training management platform of vocational education training of Internet of Things intelligent information technology.